Hydrothermal Liquefaction (HTL)

Understanding The Hydrothermal Liquefaction Process By Clean Stream Fuels

Learn in detail about the hydrothermal liquefaction process used by Clean Stream Fuels to convert waste into valuable biocrude and briquettes. Discover the benefits and applications of HTL.

We Empower Our Partners To Convert Waste Into Sustainable Biocrude and Briquettes

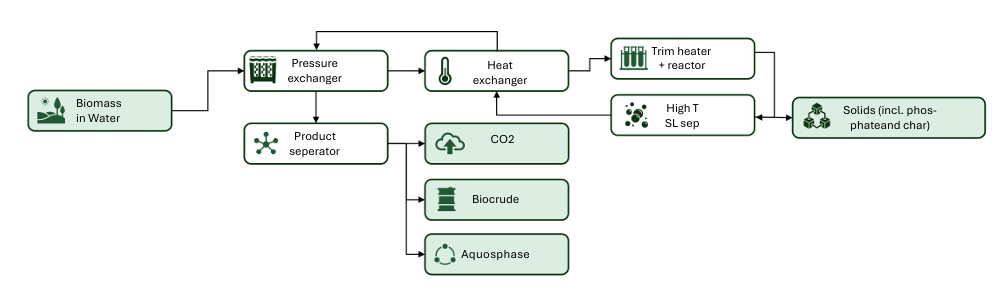

Clean Stream Fuels utilizes a cutting-edge hydrothermal liquefaction process (HTL) to efficiently transform a wide range of wet organic wastes into valuable energy resources. This innovative hydrothermal liquefaction process involves subjecting biomass to moderate temperatures and high pressures in the presence of water, mimicking the natural geological processes that create fossil fuels but at an accelerated rate. By implementing our on-site hydrothermal liquefaction process systems, we empower our partners to convert problematic waste streams into sustainable biocrude, a renewable feedstock for refineries, or high-energy briquettes for clean heat and power generation.

The Science Behind Our Hydrothermal Liquefaction Process

The hydrothermal liquefaction process at Clean Stream Fuels leverages the unique properties of water under subcritical conditions (typically between 200-350°C and 5-20 MPa). In this state, water acts as both a solvent and a reactant, effectively breaking down the complex organic molecules in the waste feedstock. The hydrothermal liquefaction process involves a series of chemical reactions, including hydrolysis, dehydration, decarboxylation, and polymerization, which ultimately convert the biomass into a liquid biocrude phase and a solid hydrochar byproduct. The gaseous phase produced is typically rich in carbon dioxide.

Key Advantages of The Hydrothermal Liquefaction Process By Clean Stream Fuels

Clean Stream Fuels: Experts in the Hydrothermal Liquefaction Process

Versatile Feedstock

Our hydrothermal liquefaction process can handle a wide variety of wet organic wastes, including sewage sludge, agricultural residues, food waste, and certain industrial byproducts, reducing the need for energy-intensive drying processes.

On-Site Conversion

Implementing our hydrothermal liquefaction process on-site eliminates the significant costs and logistical challenges associated with transporting large volumes of waste.

Valuable End Products

The hydrothermal liquefaction process yields biocrude, a renewable oil that can be further refined into transportation fuels, fertilizers and gas.

Environmental Benefits

By converting waste into energy, the hydrothermal liquefaction process helps reduce landfill waste, lowers greenhouse gas emissions, and offers a sustainable alternative to traditional waste disposal methods.

Potential for Energy Independence

For facilities generating significant organic waste, implementing our hydrothermal liquefaction process can lead to greater energy independence, savings and potential revenue generation.

Applications of Our Hydrothermal Liquefaction Process

The biocrude produced through our hydrothermal liquefaction process can serve as a sustainable feedstock for traditional oil refineries, enabling the production of renewable diesel, jet fuel, and other valuable chemicals.

Choosing Clean Stream Fuels’ hydrothermal liquefaction process offers numerous benefits: